The Saxon Metalworks shop truck is looking good

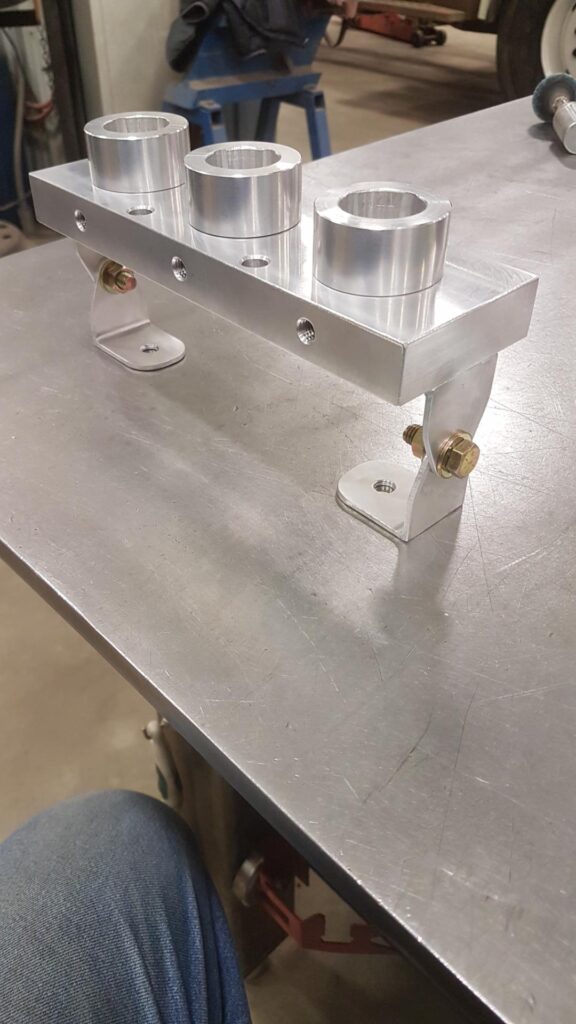

A rack to hold lathe tailstock tools

A rack to hold quick change tool post holders

A fresh coat of paint on the shop built hydraulic press

A huge upgrade in capability for the shop. A Colchester Triumph 15/50 gap bed lathe. It was made in England, has a 7 1/2 hp motor, 2 1/8″ spindle bore,16 speeds and can cut any thread imaginable. Now I have to work at getting this 3000 lb machine off the pallet and moved into place.

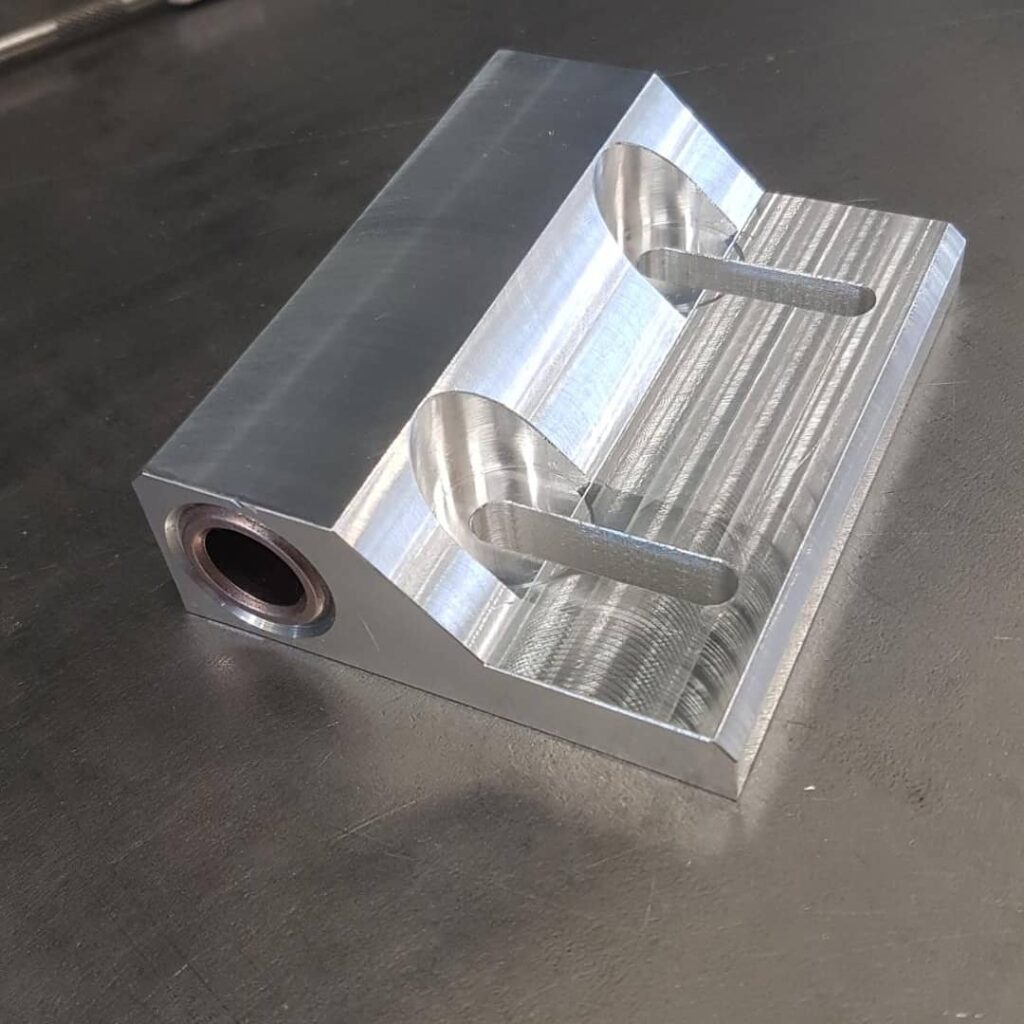

The next project. A very rough and abused 4×6 horizontal bandsaw. I completely disassembled, cleaned and inspected it, then set the base on the milling machine. I milled the bottom ends flat then fabricated a pair of pedestals and a chip pan to replace the wobbly legs. Next was to machine a new hinge and press in sintered bronze bushings. It’s a good start but lots more to do.

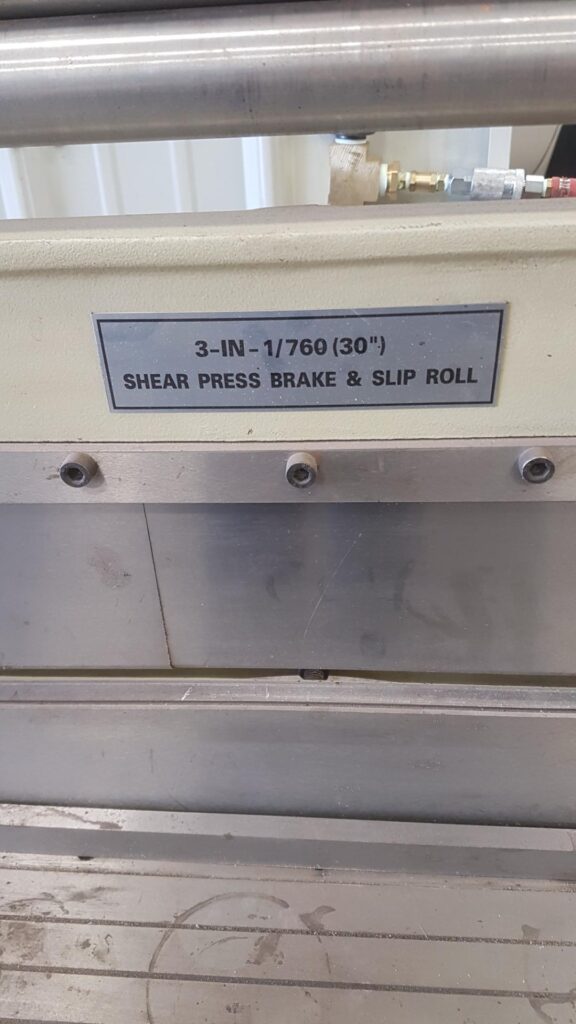

New addition to the shop. A 30″ sheet metal shear/brake/roller.

Custom grinder stand for the shop, fabricated with scrap material. It has 2 different grinding wheels, 2 different wire wheels and a belt sander.

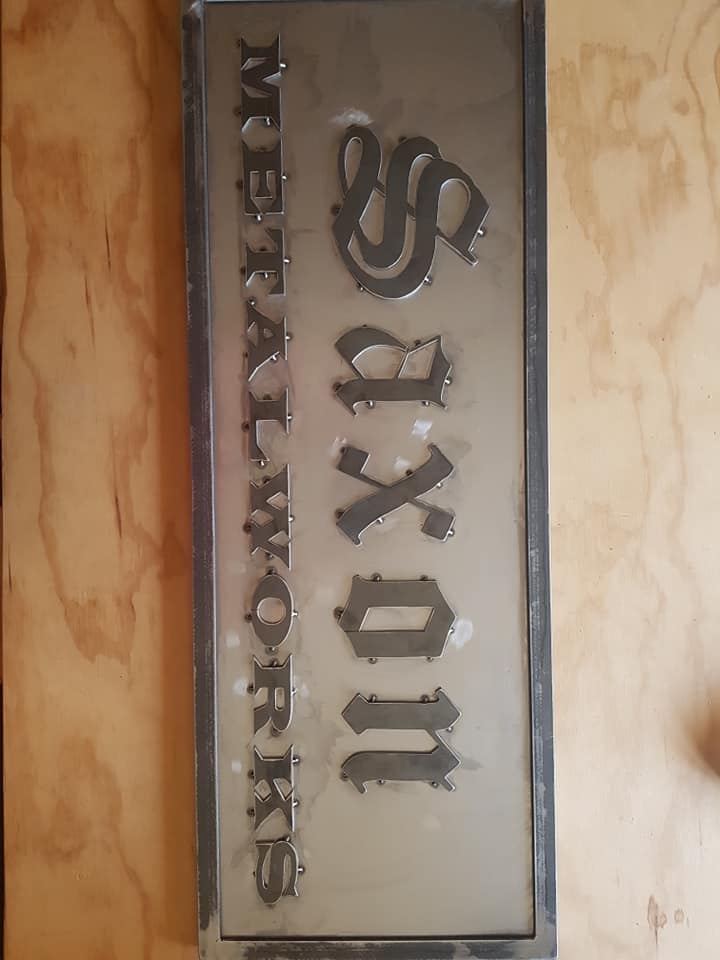

Shop sign completed and hung up on the wall!

Work in progress! 3/16″ thick steel letters for a sign I’m making for the shop

“New” milling machine and lathe

Fabricated frame to raise and level the milling machine. It lifted the mill 61/2 inches. No more sore back!